If you have recently replaced your old cabinets during a kitchen or bathroom remodel with some new fine cabinetry or perhaps you are just needing an updated work surface there are a few choices that need to be considered before making your final decision. Plastic laminates, solid surface material, granite, quartz, stainless steel, wood, and concrete are the most popular choices today when considering new or replacement countertops for a fine kitchen upgrade or bathroom makeover. Each surface has it's own set of pros and cons to take under advisement before a conclusion is reached making sure your selection blends with your lifestyle. Remember that any samples of materials that you see are only small representations of any larger piece when choosing products. Furthermore trivets and cutting boards should always be used no matter which top you choose.

Nonporous plastic laminates have been around for many years which is a testament to their durability. They represent the most affordable choice for your money and appear seamless. We've come a long way since the days of harvest gold and avocado green but some of this original material still exists in kitchens today. We now have different grades of laminate and the HD grade offers interesting designs and textures that help to hide scratches but be advised--they will scratch and the glossier the finish the worse the scratch shows. Heat should never be introduced and the use of hot pads is a necessity. Color caulks offered by the laminate manufactures matching their laminate colors are used where the top meets the splash for flexibility or integral splashes are also an option. Drop in sinks are preferable when using plastic laminate but now there are some under-mount units available. There are also many edge profiles produced today to enhance the look of your new laminate surface. Never use abrasive cleaners on any plastic laminate surfaces because they dull the existing finish.

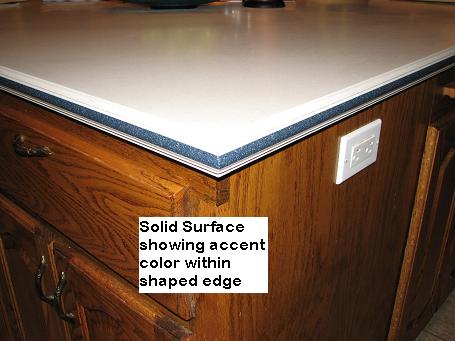

Solid surface materials like "Corian" or "Gibralter" are composed of nonporous plastic where the color is continuous throughout it's thickness. This material will stain and scratch but due to their makeup the solid surface tops can be reworked by professionally buffing out the affected areas and repairs are a possibility and is a great choice for Austin kitchen cabinets. Remember that the darker the product the more evident the scratches. These tops do appear seamless and are more bacteriostatic than stone. The pricing varies for groups A-E with the solid color A group being the least expensive. The higher priced groups give you many more color choices and variations. A matte finish with a low sheen verses the higher glossed finishes found on granite is typical. As with the laminates above there is usually no variance in color between like samples. There are no limits for the edge profiles and different colors can also be used as an accent. The use of trivets to protect from heat exposure is advisable. (see photo below)

Granites are a natural stone coming right out of the mountain so no two slabs are exactly alike. Pitting and veining are inherent of mother nature and lend to any slab's beauty. Many natural colors are available and usually lighter tops are preferred over darker stained fine cabinetry and vice versa holds true. The stones are cut and polished to a high gloss finish but this can be altered to produce a more dull surface by a process known as honing. There are different edge treatments available limited only by the fabricator. Seams are visible and accepted and only avoided by using larger pieces to limit the number of joints. One downfall of granite is it's porosity. Granite tops require maintenance and must be sealed frequently. The duration between coats is directly proportional to the amount of use your top gets. A good rule of thumb is to see if water continues to bead up when you place it on the surface. If not, reseal.

Quartz is a man made product consisting of 93% stone pieces held together by resin and dyes. It is the newest and the best rated material available today having bacteriostatic qualities. It is technically maintenance free due to it's nonporous surface and the best choice for a bathroom vanity. The colors are consistent and a uniqueness due to a natural occurrence of color concentration known as pooling can be observed. The use of this material is on average a higher cost surface. In its beginning this product contained small pieces of stone but now larger pieces are being used to create more interesting patterns. The overall look is a more uniform pattern than that of granite. It is the most scratch resistant choice out there but things do happen. The joints are not seen. Like granite there are no limits to the sinks that can be used.

Stainless steel used on counter tops has the same smudging disadvantage as is seen on appliance faces. The surface is seamless when utilizing custom welding. The typically used 16 gauge product can be configured into any shape. It is impervious to both oils and acids. It is also a higher cost option starting at around $65 per square foot. The use of cutting boards is highly advised. Standing water can cause a permanent mark.

The use of wood represents the certified green choice with no two pieces alike. Wood is both renewable and repairable. It is gentle on glassware and can be used as a cutting board. It's main drawback is the natural porosity of wood. This will cause darkening when water is left standing along with the fact that food odors are constantly being absorbed. Trivets must be used because wood expands and contracts with temperature changes. And do not forget about splinters when you aare cleaning up.

Concrete tops are poured in a mold outlining the face and edge profile. The varying colors of the substrate are accomplished by adjusting the variables within the mix like cement colors, the type of sand(s), or by the add mixes used during the mixing process. Many factors can produce shade, hue, and tone contrasts like acid etching stains used on the surface once it has been poured and set. More creative and interesting contrasts can be acheived by using additives in the mix like stainless steel filings, glow in the dark materials, or colored glass chips. Once the slab is polished it must be sealed at the rate needed per use. This process lends itself to a patina with age.

A Typical Solid Surface With A Colored and Routed Edge